When you look under the hood of a car, you might see a complex engine that seems like a puzzle. However, it’s actually composed of several important components that work simultaneously to keep your vehicle moving. At the heart of it all is the internal combustion engine which requires energy to function. Just like humans need fuel to move, this engine uses fuel to generate power. The spark from the engine ignites the fuel, creating tiny, contained explosions that produce the movement needed for the car to operate.

The engine is made up of multiple parts, each with a specific role. These include everything from the power generator to the fuel burner. Each component is crucial in ensuring that the engine moves efficiently and effectively. For example, the spark plug helps to ignite the fuel, while the pistons convert the energy into mechanical motion. Understanding how these parts interact and work together can be a bit like piecing together a Hot Wheels toy—each part is essential for the whole system to function properly.

In my experience, knowing about these basic parts not only helps in appreciating how a car works but also aids in better driving and maintenance. It’s much like having a guide to understand the components of a vehicle and how they relate to one another to ensure smooth operation. By learning about these parts, you’ll have a better grasp of what happens under the hood and how the engine powers your journey from point A to B.

What Is A Car Engine?

When we talk about the engine of a car, we’re referring to the heart of the vehicle. It is a complex machine designed to convert different forms of energy, mainly heat produced by burning gas, into force that turns the wheels and gets the car moving on the road. The engine performs its task through a chain of reactions, starting with a spark that ignites the mixture of petrol and air. As this vapor gets compressed in the sealed cylinder, it burns rapidly, causing the internal combustion that expands and releases power to drive the car.

At the core of this robust structure, we have basic parts that work together to handle the workload. The lower, heavier section is the cylinder block, which acts as the casing for the main moving parts. Above it, you’ll find the cylinder head, covering the valve-controlled passages where air and fuel enter, and the gases from combustion are expelled. Inside the block, the crankshaft converts the reciprocating motion of the pistons into rotary motion, which ultimately drives the wheels. Alongside, the camshaft controls mechanisms that open and close the valves mounted above, allowing the process to take place smoothly.

A modern engine operates using the internal combustion method, where ignition happens to release energy from gasoline. This creates the mechanical work needed to generate torque, which is then applied to the wheels. While earlier engines, such as the two-stroke Saab, were loud and emitted oily smoke from the exhaust, the principles remain similar. The pistons still move up and down inside the metal tubes of the cylinders. You can imagine it like a bicycle, where your legs are like the crankshaft, and your shins are the rods pressing the pedals. In this analogy, pressing the pedals is what drives the wheels forward.

Most engines have anywhere between two and 12 cylinders, depending on the vehicle. The piston is one of the main features, providing a high power-to-weight ratio that helps the car achieve higher speeds. Different types of engines are built with resilient metal cylinders to handle the pressure inside them. In modern vehicles, you’ll typically find four, eight, or 16 cylinders, each opening and closing at precisely the right time. The goal is to bring in fuel, combine it with a spark, and manage the gases produced from combustion, which are eventually released through the exhaust.

How Does A Car Engine Work?

In a car engine, the internal combustion process is what makes everything work. The engine converts the heat from burning gasoline into mechanical work. This energy creates torque, which is then applied to the wheels to make the car move. Imagine riding a bicycle where your legs turn the pedals, similar to how the engine’s pistons move up and down in metal cylinders, connected by rods to the crankshaft. Just like your legs power a bike’s wheels, the engine’s crankshaft powers the car’s drive wheels.The basic principles of how an engine works are rooted in the internal combustion process, which involves burning a fuel-air mixture.

This chemical reaction releases energy that forces the pistons inside the cylinders to move. As these expanding gases push the piston, the crankshaft rotates, converting this motion into power that drives the vehicle’s wheels. A typical engine might have anywhere from two to 12 cylinders, each with a piston moving inside, generating the motion needed for driving. In newer cars and hybrids, some of the power comes from electricity stored in batteries, but the internal combustion engine still plays a major role.

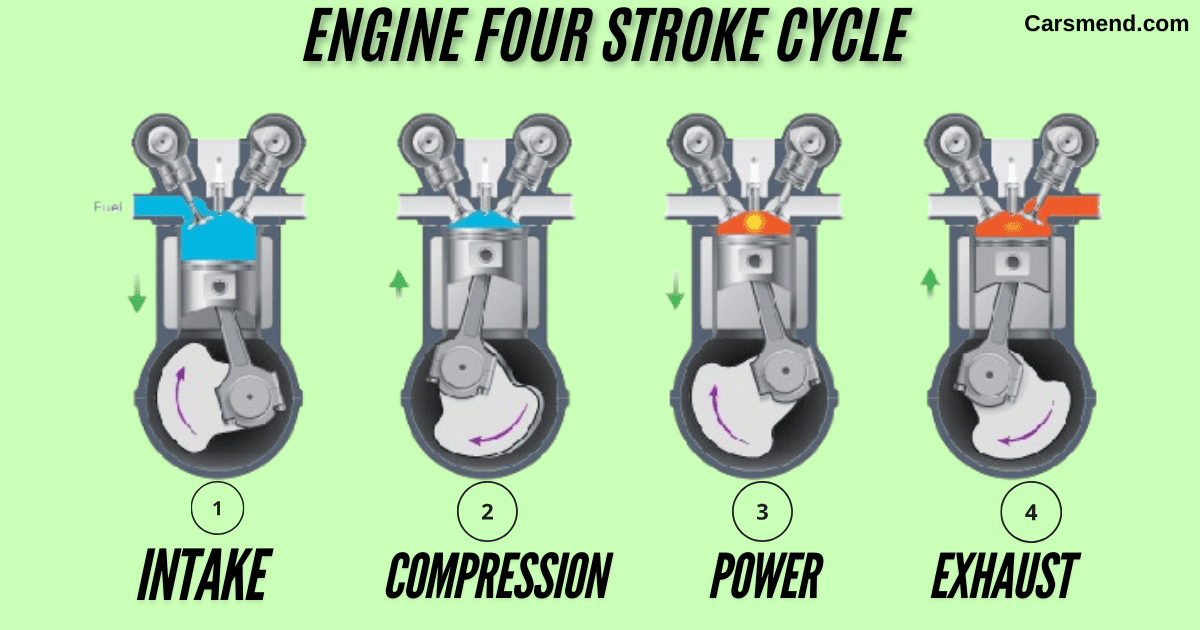

Whether it’s a Ford or a Ferrari, the explosions inside the engine happen hundreds of times a minute, creating the force that keeps the car moving forward. Each explosion pushes the piston down, rotating the crankshaft and starting the cycle over again, repeating the four-stroke combustion cycle of intake, compression, combustion, and exhaust to continuously generate energy.

But, Where Does Engine Power Come From?

The internal combustion engine works by using cylinders and pistons to create power. Inside, fuel injectors mix fuel with oxygen, and spark plugs ignite this mixture. This creates tiny, controlled explosions that happen thousands of times per minute, pushing the pistons up and down. Each power stroke generates heat and expanding gases, which drive the piston within the cylinder. As this process repeats, the energy produced powers the car, moving it forward through a series of four-stroke cycles: intake, compression, combustion, and exhaust.

>1. The Intake Stroke

The intake stroke is the first step in the engine’s combustion cycle. During this process, the piston moves down the cylinder, and the intake valve opens, allowing air and fuel to enter the combustion chamber. This movement creates a vacuum that pulls the air/fuel mixture into the engine. In port-fuel-injected (PFI) engines, this mixture is drawn in as the piston moves down, while in gasoline-direct-injected (GDI) engines, a smaller amount of fuel is injected near the end of the compression stroke, creating a more homogenous mixture.

As the piston continues to move between top dead center (TDC) and bottom dead center (BDC), the intake valve remains open, and the outlet valve is closed, ensuring that the air/fuel mixture is properly drawn in. Depending on the engine’s design and duty cycle, some engines use a combination of port and direct injection, offering flexibility in how the mixture is managed and improving efficiency.

>2. The Compression Stroke

In the compression stroke, the intake valve closes, sealing the combustion chamber as the crankshaft completes its first full revolution. The piston moves up from bottom dead center (BDC) to top dead center (TDC), compressing the air/fuel mixture tightly within the cylinder bore. Both the inlet and outlet valves remain closed, allowing the upward movement of the piston to create the necessary pressure for efficient combustion.

>3. The Power Stroke

During the power stroke, the spark plug fires and ignites the compressed air/fuel mixture at the end of the compression stroke. This ignition causes combustion, which rapidly expands the gases and forces the piston back down the cylinder bore. As the piston moves down from top dead center (TDC) to bottom dead center (BDC), the crankshaft rotates, converting this motion into power that propels the vehicle forward. Throughout this process, both the inlet and outlet valves remain closed, ensuring maximum efficiency of the power transfer.

>4.The Exhaust Stroke

In the exhaust stroke, the exhaust valve opens as the piston travels back up the cylinder for the last time, forcing the remaining gas to leave the cylinder. This is a crucial part of the combustion cycle, ensuring that used gases are expelled before the next cycle begins. As the piston moves up from bottom dead center (BDC) to top dead center (TDC), the outlet valve remains open while the inlet valve is closed. The momentum generated from the previous power stroke keeps the crankshaft moving, allowing the process to run smoothly.

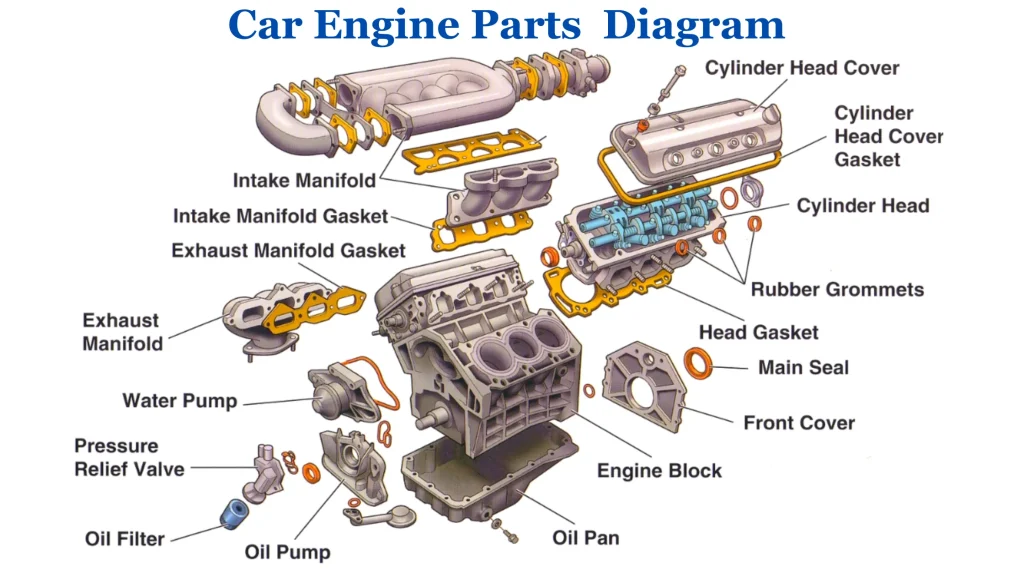

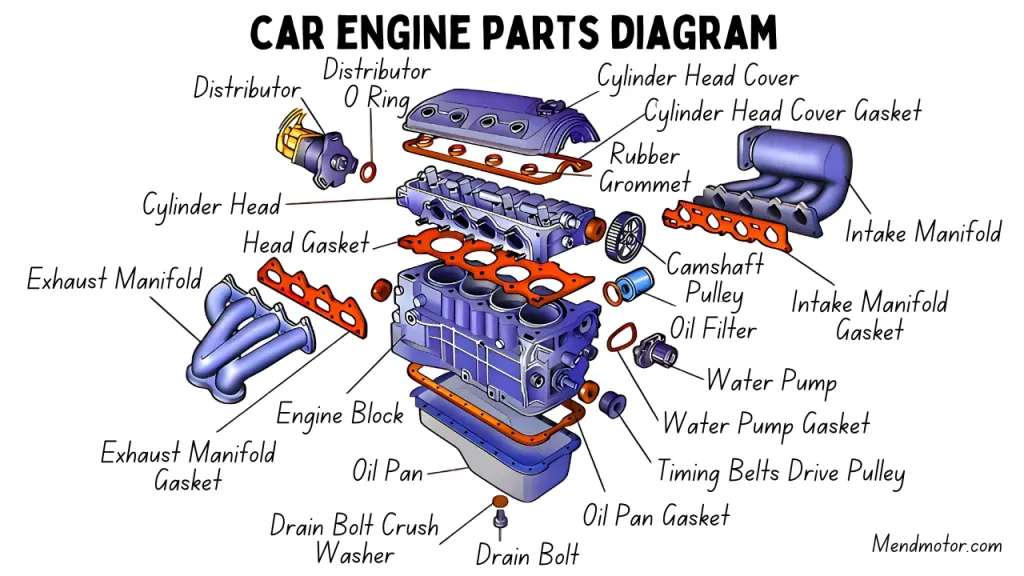

Car Engine Parts Names With Diagram

Once the used gases are pushed out, they pass through the catalytic converter to be cleaned and then exit through the muffler and tailpipe. In multi-cylinder engines, the strokes run in sequence, ensuring continuous and balanced operation. The opening and closing of the intake and exhaust valves are controlled by cams on the camshaft, which is connected to the engine’s crankshaft via a timing belt or chain. All these parts work together to maintain the engine’s efficiency, performance, and durability, with the mechanical energy ultimately moving the wheels.

List Of Car Engine Parts Names:

The engine is a major component of a vehicle, made up of several individual parts that work simultaneously to power the car. These components include everything from the engine block to the crankshaft, ensuring smooth operation. Every car engine relies on the synergy of these parts to perform efficiently.

The list of Car Engine parts

< The engine block Exhaust Manifold >

- The piston Piston Ring

- The Crankshaft Gudgeon pin

- The Camshaft Cam

- The Connecting Rod Flyweel

- Timing Belts Head Gasket

- Spark Plugs Cylinder Liner

- Cylinder Head Crankcase

- The Oil Pan Engine Distributor

- Engine Valve Distributor O Ring

- Combustion Chamber Cylinder Headcover

Intake Manifold Rubber Grommet Oil Filter

A typical internal combustion engine in a car has around 20 main parts that need to be carefully maintained and occasionally replaced as they wear out over time. Unlike an electric vehicle, which has fewer components, these engines rely on essential parts like the engine block, pistons, and spark plugs to function efficiently. Regular upkeep ensures that each part works smoothly together for optimal performance.

Parts Of A Car Engine

The engine block and cylinder block are the foundation of the car’s engine, housing essential parts like the combustion chamber and cylinder head. Within the engine, components such as the pistons, crankshaft, and camshaft are connected by the timing chain to ensure smooth operation. The valve train, including valves, rocker arms, pushrods, and lifters, works to control airflow, while fuel injectors and spark plugs deliver fuel and spark for efficient performance.

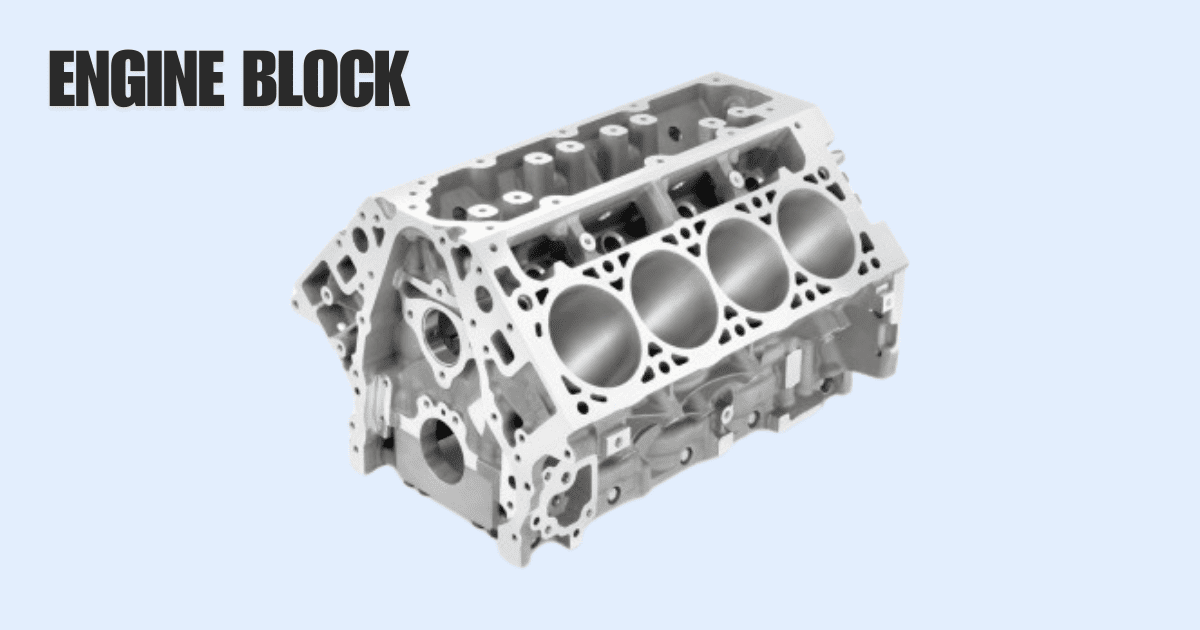

>1. The Engine Block

The engine block is the core part of a car’s engine, made from aluminum or cast iron. It houses critical major components such as the cylinders, where the pistons move up and down during the combustion process. These cylinders can range from four to twelve, depending on the vehicle’s design, and are cooled by an integrated water-cooling system. The crankshaft and camshaft are also part of the engine block, driving the wheels and controlling the movement of the valves and pistons.

Within the engine block, there are carefully designed holes and paths to allow the flow of water and oil, which help to cool and lubricate the engine’s moving parts. The water flow paths carry heat away from the cylinders, while the oil paths ensure smooth operation of the crankshaft and pistons. Without this proper flow of oil and water, the engine can overheat or seize up, damaging vital components. The cylinder head sits on top of the engine block, sealing the combustion chambers and ensuring efficient fuel burning.

At the base of the engine is the oil pan, which acts as the oil reservoir and holds the oil needed for lubrication. It connects to the oil pump and oil passages, keeping the moving parts well-lubricated. Drivers can check oil levels with the dipstick inserted into the dipstick hole, and the oil should be changed regularly at recommended intervals to ensure optimal engine performance.

Common Symptoms of Bad Engine Block

- Poor engine performance

- Low engine compression

- Visible engine smoke

- Engine overheating

- Leaking antifreeze

- Discoloration in car’s oil

- Leaking oil

- Frozen coolant

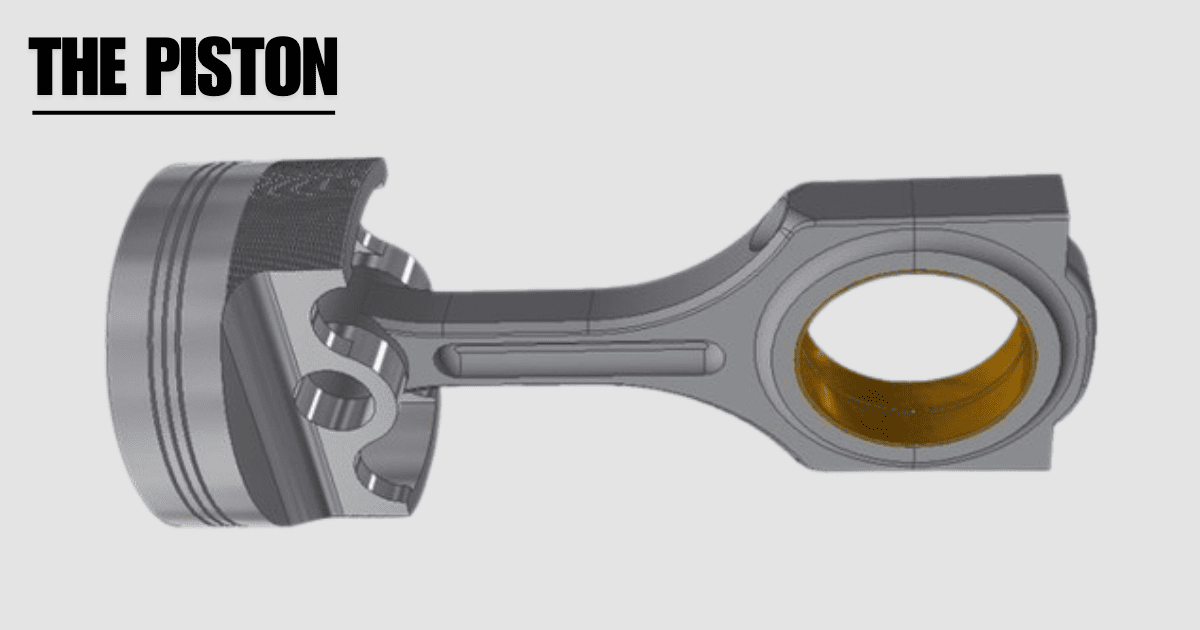

>2. The Piston

The piston is a main part of a car engine, playing a crucial role in its operation. It is a cylindrical metal component thatmoves up and down inside the engine’s cylinder. The piston rings on the piston ensure an air-tight seal, which is essential for proper compression and combustion. These rings also help in sealing the combustion chamber to prevent gas leakage and oil penetration. In a four-stroke engine, the piston goes through four stages: intake, compression, combustion, and exhaust. It connects to the crankshaft via the connecting rod and piston pin (or gudgeon pin).

As the piston moves up and down, it turns the crankshaft, which ultimately propels the vehicle. This movement generates the power needed for the engine to function effectively. The design of the piston can vary depending on the type of engine. For example, gasoline engines may have lighter and shorter pistons, while diesel engines often use heavier and stronger pistons. Regardless of the type, the piston needs to convert the pressure from the burning air-fuel mixture into force to drive the crankshaft.

In internal combustion engines (ICEs), the piston’s movement is essential for the engine’s power generation. It compresses the air-fuel mixture, which, when ignited, creates the force that drives the piston down. This force is transferred through the crankshaft to the vehicle’s wheels, propelling the car forward.

Most Common Symptoms for Bad Piston

- Loss of power while driving

- Excessive engine smoke from the exhaust

- Unusual knocking noises from the engine

- Low engine compression affecting performance

- Increased oil consumption with noticeable leaks

- Engine overheating due to poor piston function

- Rough engine idling and misfires

- Poor acceleration and sluggish response

>3.The Crankshaft

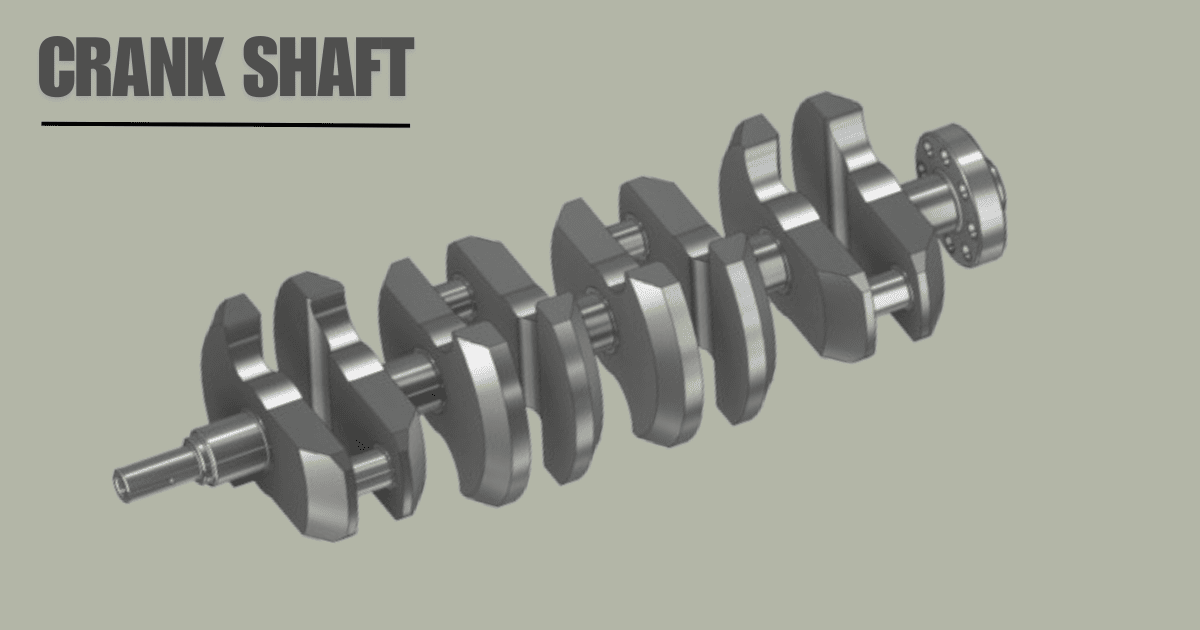

The crankshaft is a crucial part of your car’s engine that transforms the vertical movement of the pistons into horizontal, rotational energy. Positioned at the bottom of the engine block, the crankshaft is a robust component often made of steel for durability. It connects to the connecting rods which are attached to the pistons, creating a reciprocating motion that drives the car’s wheels through the gearbox and differential.

This component operates within the crankcase and is supported by large bearings at both ends. The crankshaft is connected to the flywheel and clutch, allowing it to transfer rotational energy smoothly. As it rotates, it helps drive the driveshafts and ultimately propels the vehicle forward, making it essential for the car’s movement and overall performance.

In a typical internal combustion engine, the crankshaft is designed to handle significant stress and oscillation. It is often machined and balanced meticulously to ensure smooth operation and longevity. This component’s role is vital, as it maintains the engine’s efficiency by converting the linear motion of the pistons into the necessary rotational force to power the vehicle.

Symptoms of a Bad or Failing Crankshaft Position Sensor

- Engine Misfires: The sensor’s failure can lead to improper ignition timing, causing the engine to misfire.

- Hard Starting: Difficulty starting the engine can occur if the sensor isn’t sending the correct signals.

- Check Engine Light: A malfunctioning sensor often triggers the Check Engine Light on your dashboard.

- Stalling: You might experience unexpected stalling while driving due to the sensor’s impact on engine performance.

- Erratic Idling: The engine may idle roughly or inconsistently if the crankshaft position sensor is failing.

>4.The Camshaft

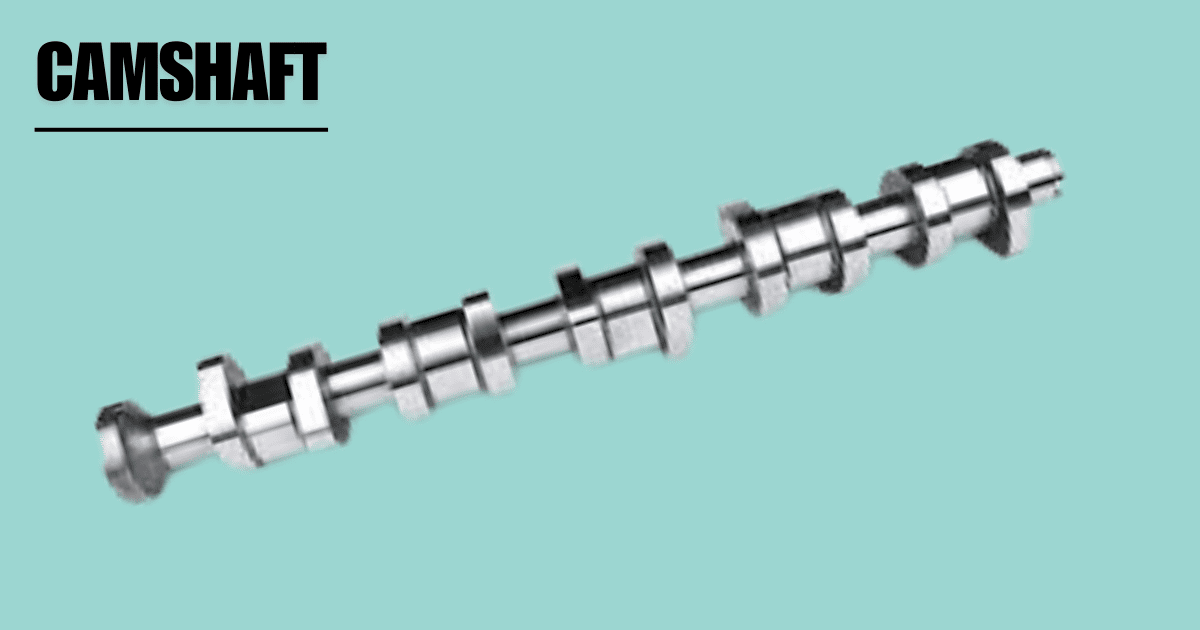

The camshaft is a crucial component of a car’s engine. It’s a rod-shaped part with cam lobes that rotate to control the valves in the engine. As the camshaft turns, its lobes push against the valves, allowing the air-fuel mixture to enter the cylinder and the exhaust gases to exit. This action is essential for the engine’s performance as it ensures the valves open and close at the right times, synchronized with the movement of the pistons.

The camshaft is typically positioned above the cylinder banks in modern internal combustion engines. It is connected to the crankshaft via a timing belt or chain, which ensures that the camshaft’s rotation is in sync with the pistons. This synchronization affects the timing of the valve openings and closings, which is critical for engine efficiency.

In modern vehicles, there are variations like Dual Overhead Camshaft (DOHC) and Single Overhead Camshaft (SOHC) configurations. These setups help manage the valves more effectively, improving engine performance and efficiency. The camshaft is usually made of strong metals or chilled iron to withstand the stresses of operation and ensure long-lasting performance.

Symptoms of a Bad Camshaft

- Active, flashing check engine light on your dashboard.

- Loss of power during acceleration or while driving.

- Popping or backfire noises from the intake manifold or exhaust.

- Loud, ticking or tapping sounds coming from the engine.

- Presence of metal debris in the engine oil.

- Cylinder misfire affecting engine smoothness.

- Increased emissions from the exhaust.

- Visible damage or extreme wear on the camshaft.

>5.The Connecting Rod

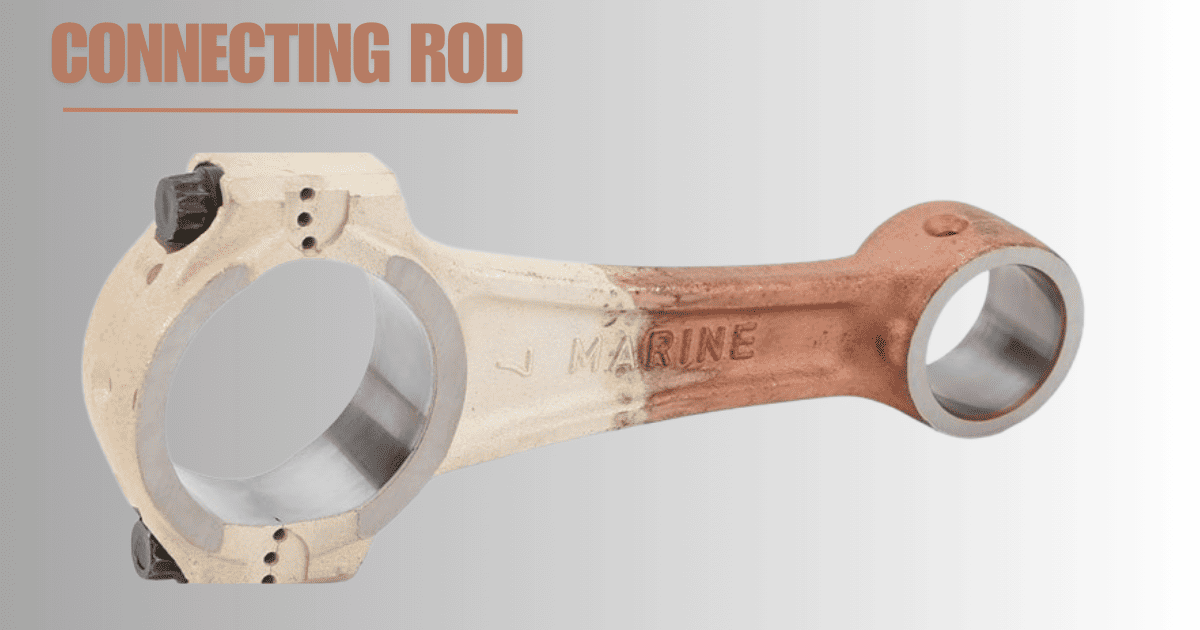

The connecting rod is a crucial engine part that links the piston to the crankshaft. Made from steel or aluminum, this metal rod has two ends: the small end, which attaches to the piston pin (also called the wrist pin), and the big end, which connects to the crankshaft via the crankpin journal. As the piston moves up and down, the connecting rod converts this linear movement into rotational motion of the crankshaft, essential for the engine’s power production.

Designed to handle the dynamic stresses of combustion, the connecting rod often comes in a one-piece or two-piece configuration, with a rod cap and bearing surface that require precise installation and removal. This component ensures the proper functioning of the internal combustion engine by allowing smooth pivoting and minimizing friction and oil clearance issues.

Symptoms of a Bad Connecting Rod:

- Engine knocking is a common sign, especially when the compression inside the engine is not balanced.

- Rod knock can be heard as a loud, repetitive noise coming from the engine when the connecting rod is damaged.

- Low oil pressure often indicates a problem with the connecting rod bearings.

- Visibly bent or damaged connecting rods can cause the engine to malfunction severely.

- Low oil levels can lead to insufficient lubrication, putting stress on the rod and causing failure.

- A damaged rod might cause uneven piston movement, leading to poor engine performance.

- If the engine experiences compression loss, the connecting rod might be at fault.

- In severe cases, a damaged rod can cause a seized engine, making it impossible to start.

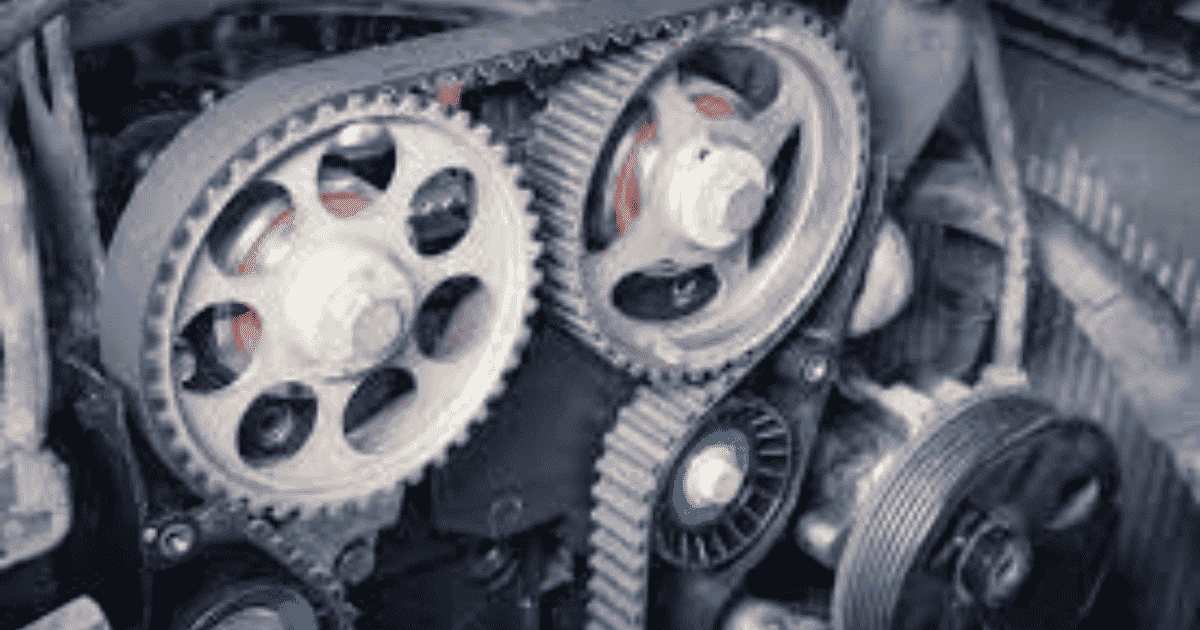

>6.Timing Belts

The timing belt plays an integral role in the smooth operation of your vehicle’s engine, ensuring all moving parts work together with precise timing for optimum efficiency. It connects the crankshaft and camshaft, making sure their rotation is perfectly synced. This harmony allows the pistons and valves to function in perfect coordination during the combustion cycle. As the camshaft opens the intake valves, it allows air and fuel to enter the cylinder. When the camshaft closes these valves, the piston moves upward, compressing the fuel/air mixture until the spark plug ignites it. This controlled explosion pushes the piston down, rotating the crankshaft and transmitting power to the rest of the engine.

Without a properly working timing belt, the engine would fail to operate efficiently, as the pistons and valves could collide or the timing would be off. Made from durable materials like synthetic rubber, neoprene, and Kevlar, the timing belt is designed to handle extreme temperature conditions and continuous driving. However, with time, wear and tear occur, often at certain miles, signaling the need to replace it to avoid slip, misfires, or even a catastrophic engine failure. Whether you have a brand-new car or a used vehicle that’s years old, keeping your timing belt in check ensures the engine continues running smoothly and efficiently.

Signs Your Car Needs a New Timing Belt:

- Ticking Noise from the Engine: A worn timing belt can cause a ticking or clicking noise as it begins to lose its tension, affecting the engine’s moving parts like the camshaft and crankshaft.

- Engine Misfires: If the timing belt slips or stretches, it can disrupt the precise timing of the pistons and valves, leading to misfires during the combustion process.

- Rough Engine Idling: When the belt becomes worn, the engine may idle roughly due to the improper synchronization of the intake and exhaust valves with the crankshaft and camshaft.

- Difficulty Starting the Engine: A bad timing belt can throw off the engine’s entire cycle, making it difficult to start the car or causing it to stall soon after starting.

- Loss of Power: As the belt deteriorates, it can cause a drop in power, especially during acceleration, since the crankshaft and camshaft rotation may not be in sync.

- Oil Leaks: Oil seeping from around the timing cover could signal a worn belt or other timing components, as the leaking oil can degrade the rubber or neoprene of the belt.

- Excessive Exhaust Smoke: If the timing belt is worn or broken, it may cause the engine to burn fuel improperly, leading to increased exhaust gases and smoke from the tailpipe.

- Belt Appearance: Physically inspecting the belt can reveal cracks, fraying, or glazing on the surface, all signs that the timing belt is failing and should be replaced soon.

>7. Spark Plugs

Spark plugs are small but vital electrical devices in any internal combustion engine. They work by creating a spark that ignites the air-fuel mixture inside the combustion chamber. This process is driven by high-voltage electricity supplied by the ignition coil, which travels through the spark plug wire to reach the spark plug. The electricity jumps across the gap between the positive and negative electrodes, igniting the mixture at the precise moment needed for the combustion stroke. When the timing is right, this controlled explosion produces power that moves the pistons and keeps the engine running efficiently.

In modern engines, the spark plug is screwed into the cylinder head, with its metal housing ensuring it stays electrically grounded. The center electrode, surrounded by a ceramic insulator, allows the high-voltage electricity to pass through without overheating. The spark gap at the inner end is where the magic happens, as the spark ignites the air-fuel mixture, triggering the combustion process. Over time, spark plugs can become fouled due to contamination or wear, which affects the ignition system’s effectiveness, making it important to regularly inspect and replace them for optimal engine performance.

Symptoms of bad spark plugs can include

- Engine Misfires: Faulty spark plugs can cause the air-fuel mixture in the combustion chamber to not ignite properly, leading to engine misfires and rough running.

- Poor Fuel Economy: Worn or fouled spark plugs result in incomplete combustion, making the engine use more fuel to compensate for the loss of power.

- Difficulty Starting the Engine: Bad spark plugs struggle to generate the necessary spark, making it hard for the engine to start, especially in cold conditions.

- Lack of Acceleration: If the spark plugs are not functioning effectively, you may notice slower acceleration or a lack of response when pressing the gas pedal.

- Rough Idling: A bad spark plug can cause the engine to idle roughly, with vibrations and stuttering due to poor combustion.

>8. Cylinder Head

The cylinder head sits at the top of the engine block, sealing the combustion chamber and housing critical moving parts like valves, camshafts, and fuel injectors. Designed to withstand the intense pressures and high temperatures generated during combustion, it ensures smooth airflow and fuel deployment into the cylinders. The head gasket forms a tight seal between the cylinder head and the main engine block, preventing leaks and maintaining the engine’s efficiency.

Cylinder heads are made from cast iron or aluminum. While cast iron is more durable and can handle extreme conditions, it is also heavy and more expensive. On the other hand, aluminum heads are lighter and offer better heat dissipation efficiency, making them popular in high-performance and racing cars. However, issues like overheating, coolant loss, or head gasket failure can lead to cylinder head failure, potentially causing irreparable damage to the engine if not addressed.

- Symptoms of a Cracked Cylinder Head:

- Overheating Engine

- Coolant Loss

- White Smoke from Exhaust

- Poor Engine Performance

- Oil Contamination (milky or frothy oil)

- Coolant Contamination (oil in the coolant)

- Visible Coolant Leaks

- Engine Misfires

>9. The Oil Pan

The oil pan is a crucial part of the engine, attached to the bottom of the engine with bolts and acting as a reservoir for the engine’s oil. Its main job is to store the oil, which is pumped through the engine to lubricate, clean, and cool the moving parts. The oil pump draws the oil from the pan and pushes it through the filter, which removes dirt and debris before the oil circulates back into the engine. Made from steel or aluminum, the oil pan holds several quarts of oil, which you can check using a dipstick to measure the oil level.

Over time, the oil pan may develop leaks due to wear on the gaskets or seals, or if it’s hit by a hard object while driving, especially in off-road conditions. A damaged pan or drain plug that is overtightened can cause oil to seep out, reducing the engine’s ability to run smoothly. It’s important to check and maintain the oil pan regularly, especially after several miles, to ensure it functions as the primary source of oil circulation in the engine.

Symptoms of a Bad Oil Pan

- Low Oil Warning Light Activates: The indicator light on your dashboard alerts you to low oil levels, suggesting a potential issue with the oil pan.

- Oil Puddle Under the Vehicle: Finding a pool of oil beneath your car indicates that the oil pan may be leaking.

- Unexpected Drop in Oil Level: A sudden decrease in the oil level can signal a problem with the oil pan, potentially due to a crack or leak.

- Engine Overheating: If the engine temperature rises beyond normal, it might be due to insufficient oil flow from a damaged oil pan.

- Burning Smell from the Engine: A noticeable burning odor can occur if oil is leaking onto hot engine parts, often pointing to an issue with the oil pan.

>10. Engine Valve

Car engine valve play a crucial role in managing the flow of gases within the engine’s combustion chamber. They are designed to open and close at precise moments to regulate the air-fuel mixture entering the cylinder and to allow exhaust gases to escape. The camshaft controls the valves by pushing them open and closed through a linkage system, ensuring they operate at the correct time during each stroke of the engine cycle.

These valves are synchronized with the pistons and the timing mechanism, either a timing belt or a timing chain, which ensures everything stays in sync. The camshaft, located in the cylinder head, pushes the pushrods that move the rocker arms, adjusting the valves with each rotation. This careful coordination allows the engine to run efficiently at various speeds, facilitating smooth combustion and optimal performance.

The symptoms of bad valves include:

- Engine Misfires: Bad valves can cause incomplete combustion, leading to engine misfires and rough running.

- Reduced Power: If the valves are not opening and closing correctly, the engine may lose power and acceleration.

- Poor Fuel Economy: Faulty valves can disrupt the air-fuel mixture, causing the engine to consume more fuel than usual.

- Rough Idling: A noticeable roughness or vibration while the engine idles can indicate issues with the valves.

- Excessive Smoke: You might see smoke from the exhaust if the valves are not sealing properly, allowing oil or fuel to burn incorrectly.

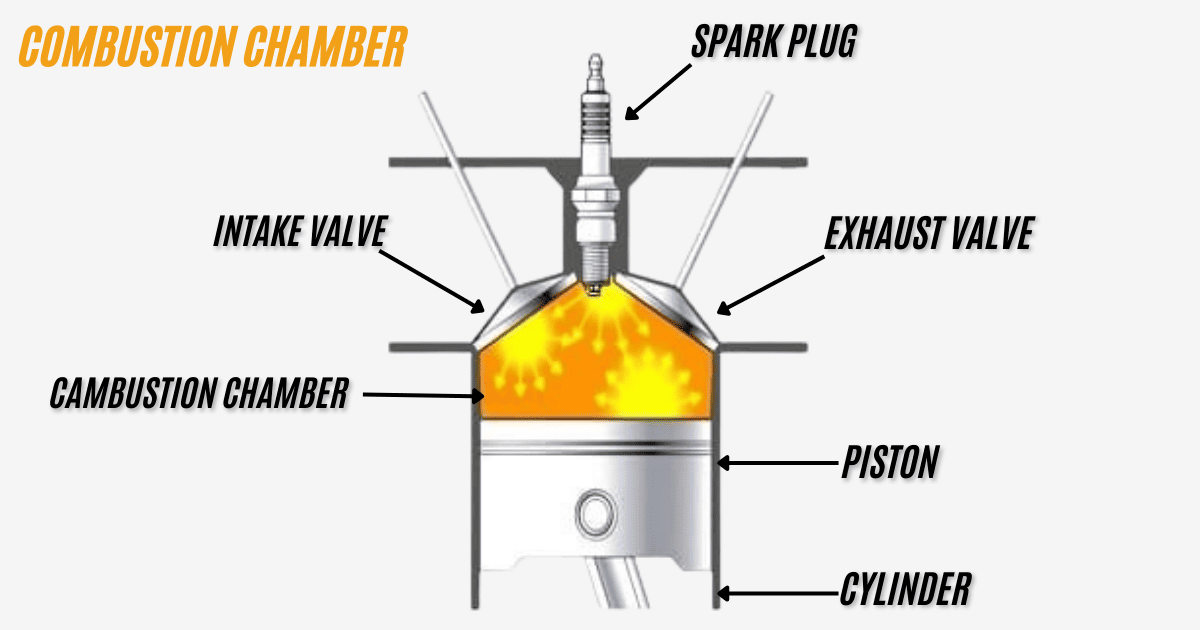

>11. Combustion Chamber

The combustion chamber is a crucial area within the cylinder where the fuel and air mix and are ignited. This mix is compressed by the piston to create high pressure and temperature, which causes the fuel to combust. The spark plug ignites the air-fuel mixture, causing an explosion that pushes the piston down and generates energy to power the engine.

The main function of the combustion chamber is to burn the air-fuel mixture efficiently to produce high-pressure gases. These gases push the piston, converting the energy from the combustion into mechanical power. Valves control the flow of the mixture into and out of the combustion chamber, ensuring it operates correctly during the engine’s cycle.

Problems in the combustion chamber can lead to issues like oil burning or blue exhaust smoke if oil seeps into the chamber through worn valve seals or piston rings. Ensuring the combustion chamber is in good condition is essential for maintaining engine performance and efficiency.

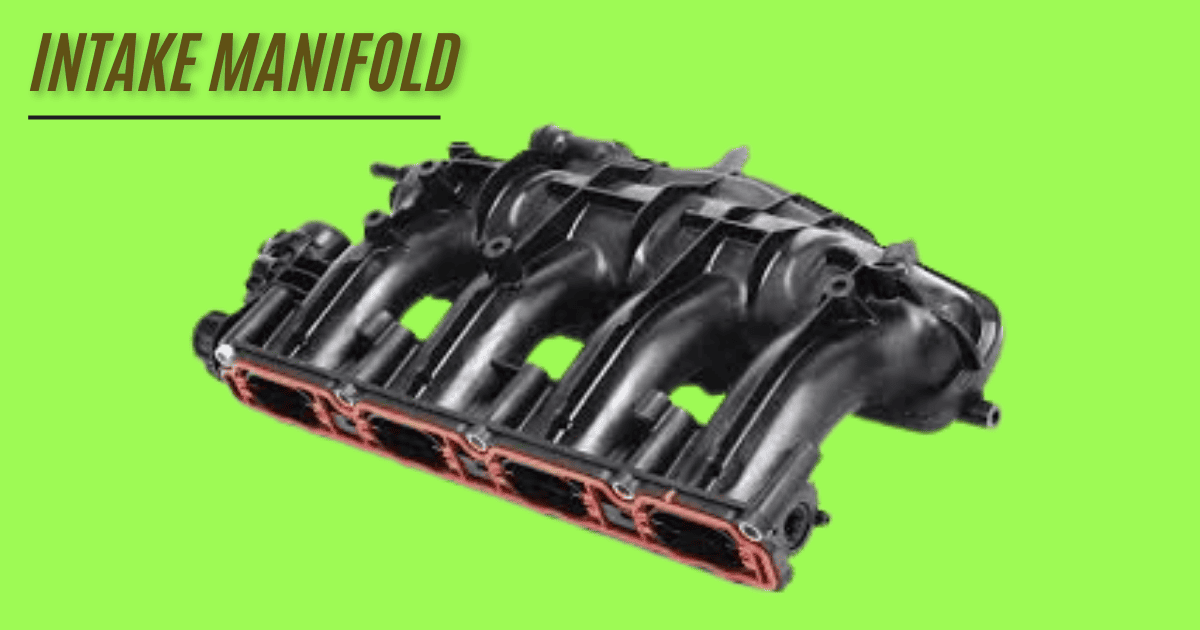

>12. Intake Manifold

The intake manifold is an essential component of the engine that distributes air evenly to the cylinders. It channels air from the air cleaner to the fuel injectors, where it mixes with fuel. This air-fuel mixture then enters the combustion chamber during the intake stroke of the engine’s cycle. In older cars, this function was handled by a carburetor and throttle body.

Modern intake manifolds are typically made of aluminum, cast iron, or plastic, and are designed with a plenum and runners to effectively manage airflow. The manifold ensures that air reaches each cylinder in a balanced manner, optimizing engine performance. Regular maintenance, including changing the air filter to prevent dust and foreign particles from entering, helps keep the manifold functioning properly.

Symptoms Of a Bad Intake Manifold:

- Rough Idling: A failing intake manifold can cause uneven air distribution, leading to a rough idling or vibration when the engine is running.

- Poor Acceleration: If the intake manifold is not working correctly, the engine may struggle to accelerate smoothly, showing a noticeable drop in performance.

- Increased Engine Temperature: An issue with the intake manifold can lead to improper air-fuel mixture, causing the engine to run hotter than usual.

- Check Engine Light: Problems with the intake manifold often trigger the check engine light on your dashboard due to errors detected by the engine’s sensors.

- Vacuum Leaks: A damaged intake manifold can cause vacuum leaks, which may lead to a hissing noise from the engine and affect its overall performance.

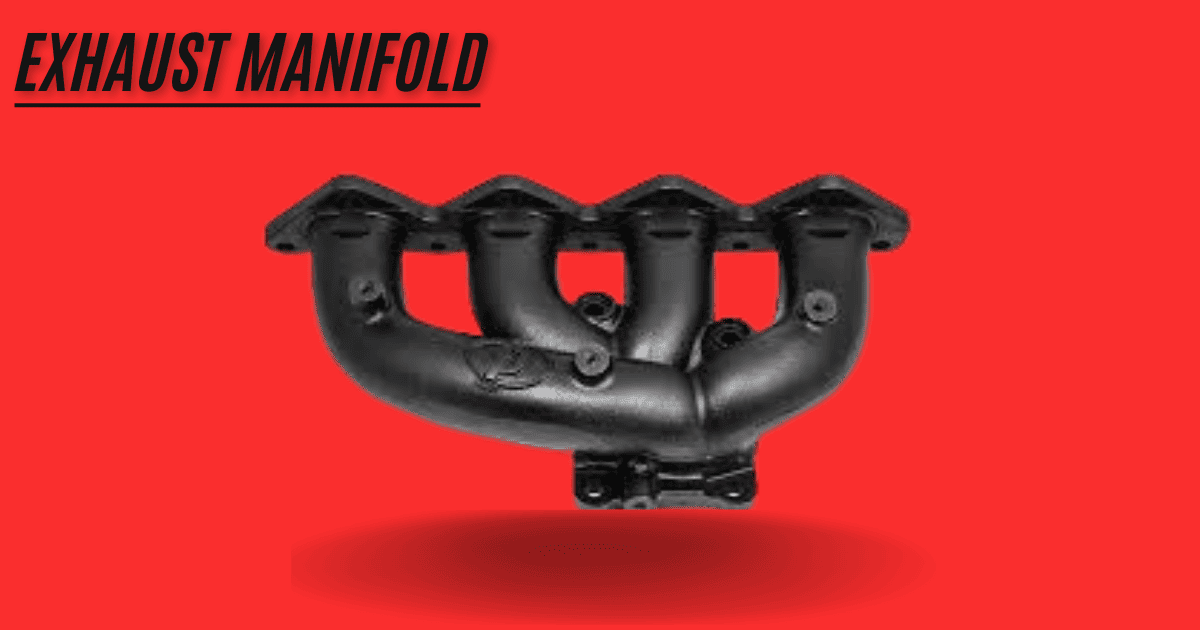

>13. Exhaust Manifold

The exhaust manifold is a crucial part of the exhaust system that collects exhaust gases from each cylinder of the engine and funnels them into a single pipe. It is attached to the engine block and is designed to direct these gases towards the catalytic converter. This helps in managing the gases produced during the combustion process, ensuring they are properly treated before exiting the vehicle.

A faulty exhaust manifold can lead to several issues. If there’s a leak in the manifold or its gasket, exhaust gases might escape, which can be harmful to the health of the vehicle’s occupants and result in erroneous readings from the oxygen sensor. Additionally, larger holes or cracks in the manifold can produce a loud exhaust noise, indicating a potential problem. Regular inspection and maintenance are essential to keep the exhaust manifold functioning properly.

Symptoms of a Cracked or Bad Exhaust Manifold:

- Loud Exhaust Noise: A cracked or damaged exhaust manifold often produces a loud noise. This happens because the gases escaping from the cracks create a noticeable sound.

- Exhaust Leaks: If the exhaust manifold has a leak, exhaust gases might escape, which can lead to a dangerous health hazard for the vehicle’s occupants. You might notice a strong smell of exhaust gases inside the cabin.

- Check Engine Light: A faulty exhaust manifold can cause incorrect readings from the oxygen sensor, triggering the check engine light on your dashboard.

- Poor Engine Performance: Cracks in the manifold can disrupt the flow of exhaust gases, affecting the engine’s performance. You may experience reduced power and poor acceleration.

- Increased Engine Temperature: A damaged exhaust manifold can cause the engine to run hotter than usual due to inefficient exhaust gas flow and poor heat dissipation.

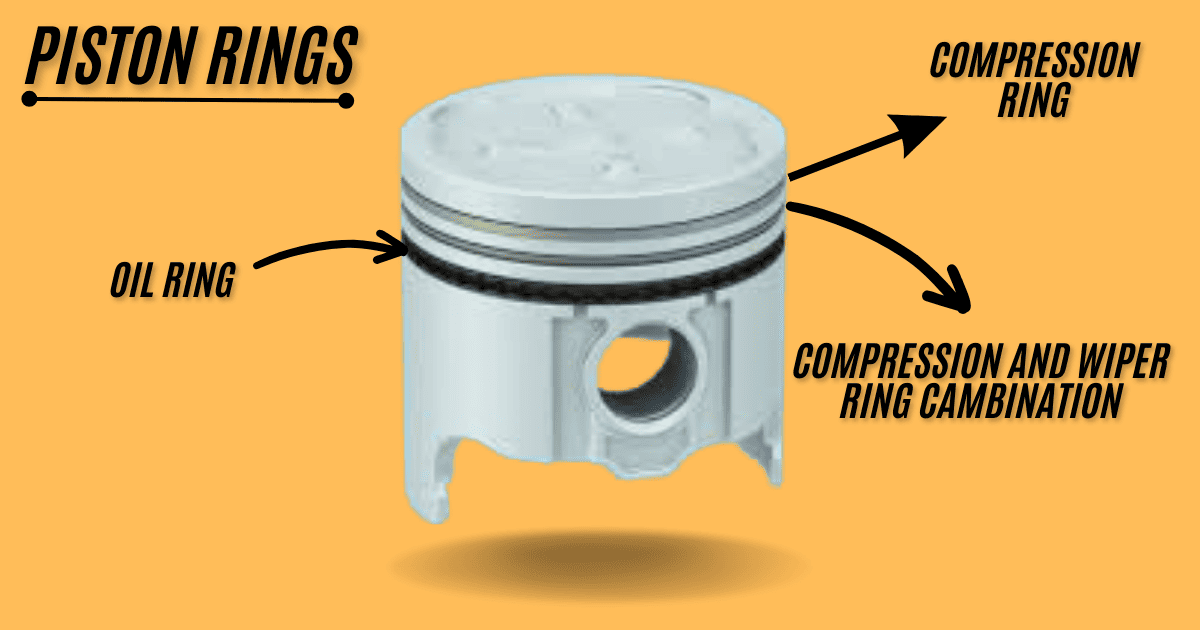

>14. Piston Ring

A piston ring is a crucial metallic ring that fits around the piston in your engine. It helps create a seal between the piston and the cylinder wall, maintaining the proper compression and preventing gases from escaping into the crankcase. This seal is essential for minimizing loss of combustion gases, improving heat transfer, and controlling oil consumption.

If the piston rings are worn out or damaged, you might notice several problems. Engine misfires and rough idling can occur because the engine struggles to maintain proper compression. You may also see discolored smoke from the exhaust, which indicates that excess oil is burning in the combustion chamber. Increased oil consumption and poor acceleration are common signs of piston ring issues.

Proper maintenance of the piston rings ensures effective compression, oil control, and heat transfer, which helps in preventing excessive wear and damage to the cylinder. If you observe symptoms like low performance or high oil consumption, it’s wise to have the piston rings inspected and replaced if necessary.

>15. Gudgeon Pin

The gudgeon pin, also known as the wrist pin, is a crucial component in a car engine. It serves as the connection between the piston and the connecting rod, allowing these parts to work together smoothly. This pin acts as a pivot, enabling the piston to move up and down within the cylinder while transferring motion to the connecting rod. Made from high-strength alloy steel, the gudgeon pin is designed to withstand significant forces and wear.

In internal combustion engines, the gudgeon pin ensures that the piston and connecting rod operate in unison. It fits into a bearing in the piston and is held in place by the connecting rod. Proper functioning of the gudgeon pin is vital for efficient engine operation and longevity, as it directly impacts the engine’s performance and reliability.

>16. Cam

The cam is a crucial mechanical piece in a car engine. It’s part of the camshaft, which rotates and transforms rotary motion into linear motion. This transformation is essential for controlling the opening and closing of the valves. The cam achieves this by striking a lever that moves in a circular path. The shape of the cam affects how the engine operates, influencing the timing of the air-fuel mixture entering and exiting the combustion chamber.

In essence, the camshaft has cams that rotate and convert the motion, allowing the valves to open and close at precise times. If the cam’s shape is worn or improperly designed, it can disrupt the engine’s performance by altering the timing of the valve movements. This can lead to issues with air-fuel mixture management and overall engine efficiency.

>17. Flywheel

The flywheel is a crucial component in the engine, acting as a thick metal disc usually made from cast iron, steel, or aluminum. It is bolted to the end of the crankshaft and is essential for smoothing out the engine’s power delivery. The flywheel helps balance the engine by storing and releasing rotational energy, which minimizes vibration and noise. Its heavy, rigid design ensures that the engine runs more smoothly by counterbalancing the irregularities in power produced during the combustion process.

In addition, the flywheel plays a significant role during engine start-up. The starter motor engages with the starter ring on the edge of the flywheel to initiate engine rotation. This interaction ensures the engine gets the initial rotational energy needed to start. When the clutch pedal is pressed, the clutch disc disengages from the flywheel, allowing for smooth gear changes. When the pedal is released, the flywheel helps maintain momentum and smooth power transfer to the wheels.

In summary, the flywheel is vital for balancing engine operation, aiding in a smooth start, and ensuring consistent performance by mitigating vibration and noise.

Symptoms of a Bad Flywheel:

- Slipping Gears: Difficulty in gear changes or gear slippage can signal a problematic flywheel.

- Rough Idling: Engine vibrations or rough idling might indicate issues with the flywheel not balancing engine forces properly.

- Grinding Noises: Unusual grinding sounds when starting the engine or shifting gears can point to a faulty flywheel.

- Difficulty Starting: Problems starting the engine may be due to a bad flywheel affecting the starter motor.

- Shuddering or Vibration: Excessive shuddering or vibration during engine operation can be a sign of a malfunctioning flywheel.

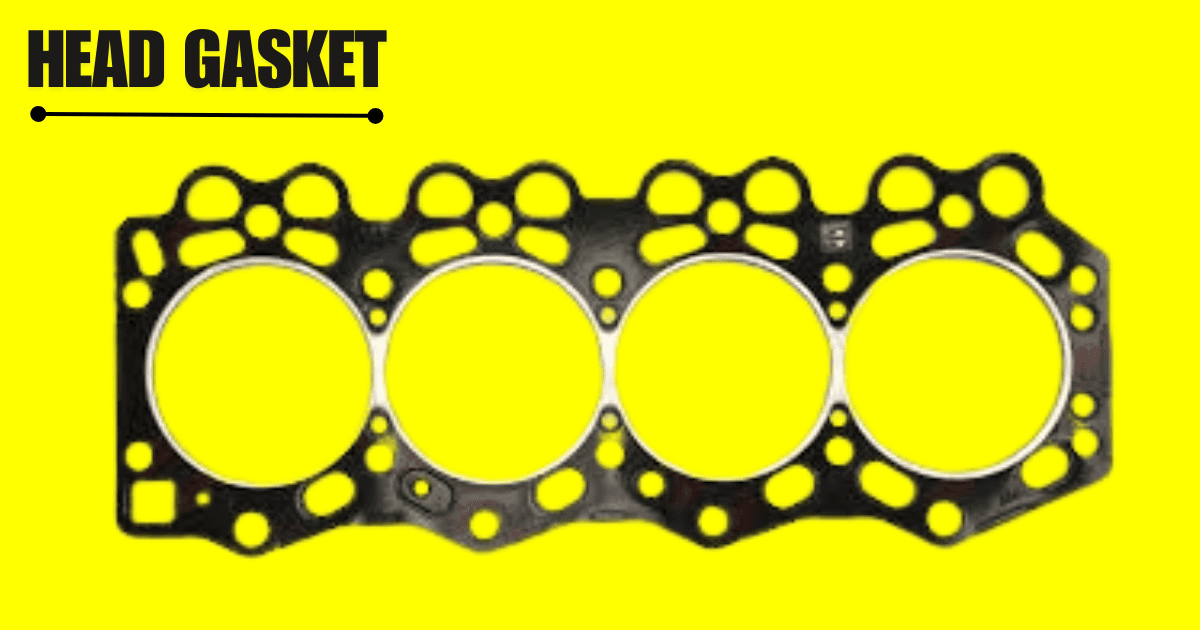

>18. Head Gasket

The head gasket is a crucial part of a car’s engine, serving as a seal between the engine block and the cylinder head. This component is responsible for maintaining proper compression within the combustion chamber and ensuring that coolant and oil do not mix. It prevents combustion gases from leaking out and keeps coolant and oil from crossing into each other, which is essential for efficient engine operation.

If the head gasket fails, you might notice issues like oil and coolant mixing, engine overheating, or white smoke from the exhaust. A damaged head gasket can lead to serious engine problems if not addressed promptly.

Bad head gasket symptoms:

- Engine overheating due to loss of coolant.

- White smoke from the exhaust, which indicates coolant is burning.

- Milky oil or oil in coolant, showing that oil and coolant are mixing.

- Loss of engine power or rough idling because of compression loss.

>19. Cylinder Liner

In a car engine, the cylinder liner is a crucial component that lines the interior of the engine block. This metallic sleeve is designed to provide a smooth sliding surface for the piston rings. The liner helps seal the combustion chambers, managing high temperature and pressure generated during the engine’s operation. It also ensures that gases don’t escape and that the engine runs efficiently.

Cylinder liners are typically made from cast iron or alloys that include nickel, chromium, molybdenum, and vanadium to enhance durability and wear resistance. They come in various types, including wet liners, which use coolant to regulate heat, and dry liners, which are usually used in air-cooled engines. Proper maintenance of cylinder liners is essential, as cracks, scoring, or wear can lead to significant engine issues.

>20. Crankcase

The crankcase is the central part of a car engine, playing a crucial role in housing vital components. It houses the crank mechanism, pistons, cylinders, and connecting rods, all of which are necessary for the engine’s movement. This part connects the transmission and gearbox, making it essential for the control system. The cylinder head is also attached to the crankcase, and it supports the engine’s internal functions, such as oil and cooling channels for lubrication purposes.

The crankcase is a complex structure, often cast to handle the pressure of the combustion process. It includes accessories like oil reservoirs and cooling systems to keep the engine running smoothly. The design helps manage lubrication and cooling, ensuring that the engine operates efficiently, making it a critical component for maintaining the engine’s overall performance.

>21. Engine Distributor

The distributor is a crucial component of the engine’s ignition system, responsible for delivering high-voltage electrical power to the spark plugs at the correct time. It plays a key role in making sure the car runs smoothly by routing electricity from the ignition coil to the cylinder. The distributor cap and rotor help direct the spark to each plug in the right sequence, igniting the air-fuel mixture that allows the engine to run.

In modern cars, the distributor is often electronic or computer-controlled, with sensors determining when and how the spark should be sent. However, in older models, if you hear strange noises, like a high-pitched squeak under the hood, it could be a sign of failure. This can lead to engine performance problems, stalling, or even a cold start issue. The distributor ensures the engine runs in unison, minimizing any exhaust emissions and keeping the vehicle operating efficiently.

Signs you might have a faulty distributor:

- Engine misfires or backfiring – the engine may hesitate or jerk while running.

- Difficulty starting the car, especially during cold weather.

- Unusual noises like a high-pitched squeak or rattling coming from under the hood.

- The car may experience stalling or shaking at idle.

- Poor engine performance, with reduced power or acceleration.

- Increased exhaust emissions or fuel consumption.

- Visible damage to the distributor cap or rotor.

>22. Distributor O Ring

The distributor o-ring is a small but crucial rubber ring that seals the distributor housing to prevent oil leaks from the engine. If the o-ring fails, oil can leak at the base of the distributor, causing grime to build up on the engine’s exterior and affecting performance. Common symptoms of a faulty distributor o-ring include engine misfires, loss of power, and oil seeping around the distributor. A driver may notice their vehicle is not running as smoothly, or it may need to be serviced more often.

This round seal plays an important role in keeping the engine properly aligned and preventing timing problems or damage to the spark plugs. It also protects the distributor from dirt, debris, and excessive heat. Regular maintenance, such as getting the vehicle tuned up every 30,000 miles, helps avoid premature wear. If you spot an oil leak, it’s essential to get the o-ring replaced by a professional mechanic to prevent further issues.

Symptoms of a Bad or Failing Distributor O Ring:

- Oil leaking around the base of the distributor, which can be easily spotted under the hood.

- A noticeable lack of power while driving, especially during acceleration.

- The engine running rough or hesitating, often making it feel less smooth.

- Frequent engine misfires, which can cause jerking or uneven operation.

These symptoms suggest that the o-ring isn’t sealing properly, allowing oil to leak and impact the engine’s performance.

>23. Cylinder Headcover

The cylinder head cover is a crucial metal component that covers the cylinder head, creating a sealed space to prevent leaks and protect the internal combustion engine. It helps contain blow-by gases from the combustion process and prevents oil droplets from escaping the lubricant system. Made from cast iron or aluminum alloy, the cover also aids in heat dissipation while housing important parts like intake valves, exhaust valves, and lifters. By sealing the top of the engine, it ensures the operational activity runs smoothly.

>24. Rubber Grommet

A rubber grommet is a round rubber item commonly used in the automotive industry to protect metal parts from chafing and vibration. It serves as a seal for various engine parts, ensuring abrasion resistance and temperature resistance for everyday use. These grommets are often placed in holes in the engine body to prevent damage to electrical wires, tubes, or hoses by shielding them from physical abrasion. They also help prevent water and dust from entering, improving engine performance and overall durability.

>25. Oil Filter

An oil filter plays a vital role in maintaining your car engine’s oil by capturing contaminants such as dust, dirt, and metal fragments. It ensures clean motor oil flows through the engine, preventing harmful particles from causing irreparable damage to the internal parts. Acting like the kidneys of the engine, the oil filter helps keep the oil in the right place and at the right time, improving the car’s overall performance and extending the life of the engine.

The oil filter works by allowing dirty oil to enter through the perforated holes in the bottom plate and pass through the filter media. This media, often made from synthetic fiber, catches impurities while letting clean oil return through the central hole to be circulated back into the engine. Without regular filtering of waste and junk, the oil pressure can drop, and unfiltered oil could circulate, leading to potential engine failure.

To avoid these problems, manufacturers recommend replacing the oil filter with every second oil change, typically between 3,000 to 6,000 miles. However, the filter may need to be changed more frequently depending on driving conditions and oil quality, ensuring the engine runs smoothly and efficiently.

Common Engine Problems

One of the major engine problems that can arise involves poor compression, which leads to a loss of power and misfiring. When your car begins to behave differently, showing signs like a no-start or rough idle, it may be due to worn parts such as pistons, rings, or even a cracked engine block. This can result in coolant leaks, overheating, or blue smoke coming from the exhaust.

Hearing rattling, tapping, or ticking sounds could point to broken rods, bearings, or pins, as these mechanisms wear down over time. Low oil pressure can also lead to metal shavings in your engine oil, which is a symptom of internal damage. The acceleration might feel sluggish, making it harder to propel the vehicle smoothly.

Regular maintenance like oil changes, fluid flushes, and checking belts and hoses is key to preventing these complicated problems. These simple tasks can help extend the longevity of your engine and avoid a failed engine.

FAQs.

What Is An Engine?

An engine is a machine designed to convert various forms of energy into mechanical energy. In modern vehicles, the internal combustion engine (ICE) is the most common type, where fuel is ignited to create a reaction that moves mechanical parts. This process allows the motor to propel the vehicle by transforming the chemical energy of fuel into the kinetic energy needed for motion.

How Does A Car Engine Work?

A car engine operates by using a fixed cylinder where a moving piston is located. When combustion gases expand, they push the piston down. This action causes the piston to rotate the crankshaft, which is part of the engine’s system. The crankshaft then turns the gears in the powertrain, which ultimately drives the vehicle’s wheels and creates motion.

What Are Th e Different Parts Of An Engine?

An engine includes key parts like the engine block, cylinders, and combustion chamber. Pistons move inside the cylinders, powered by the crankshaft and camshaft. The timing chain controls the valve train, which consists of valves, rocker arms, pushrods, and lifters. Fuel injectors and spark plugs ensure proper fuel delivery and ignition.

How Many Parts Are In A Car Engine?

A typical internal combustion engine has over 200 parts that need to be maintained and replaced over time due to wear. On the other hand, an electric vehicle has significantly fewer, with about 20 parts in total.

What Engine Does My Car Have?

To identify your car’s engine, you don’t need to be an expert. Simply check the VIN number, which can be found under the hood or in the owner’s manual. The eighth digit of the VIN contains crucial information about your engine type. This small detail reveals everything you need to know about your car’s engine, helping you understand its performance and specs.