An engine is like the heart of a vehicle, providing the power needed to drive it. It works by converting energy, such as burning fuel or using electricity, into motion. In an internal combustion engine, a spark ignites a mixture of compressed air and fuel, causing it to burn and expand, which turns the pistons and makes the wheels move. There are many different types of engines, including car engines, electric propulsion systems, and more. Each type uses a unique design and fuel to achieve the same goal – to propel a vehicle down the road. Whether you’re a novice or an experienced driver, understanding these engines can deepen your knowledge of how vehicles work.

What Is An Engine?

An engine is a machine designed to convert energy into mechanical power, enabling vehicles to move. The most common type, the internal combustion engine (ICE), uses fuel like gasoline or diesel to create explosive heat inside a cylinder. This heat causes the fuel to burn, which generates mechanical energy by forcing pistons to expand and move. The pistons are connected to a crankshaft, which then rotates and drives the wheels of the vehicle. This process involves complex reactions and is central to the function of cars, where it powers the vehicle down the road. Hybrid powertrains and electric engines are growing alternatives, providing more efficient options in modern vehicles.

In addition to internal combustion engines, there are also electric motors that convert electrical energy into mechanical motion. These motors are commonly found in electric vehicles (EVs), which offer a cleaner, more efficient way to drive without relying on traditional fuels. Electric motors work by using electric current to generate magnetic forces that move the motor’s parts. Hybrid engines combine both technologies, using gasoline and electric power to provide more efficiency. As an engineer working in this field, I’ve seen how different types of engines – from traditional gasoline engines to electric motors – play a key role in shaping the future of automotive manufacturing. Car engine parts (with diagrams) play an essential role in illustrating these systems.

How car engine work?

When you turn the key to start your car, you’re setting off a complex process that involves internal combustion engines. In these engines, fuel and air mix and are drawn into cylinders. Inside the engine, this mixture is burned, releasing chemical energy in the form of heat. This heat causes small explosions, or controlled combustion, that push pistons up and down. The force generated from this combustion process is used to turn the crankshaft, which is connected to the powertrain and ultimately moves the wheels of the vehicle. The entire process happens in a series of four strokes: intake, compression, combustion, and exhaust.

In modern vehicles, including late-model cars, hybrid and electric engines work differently, but the goal is still the same: to move the vehicle. With internal combustion engines, the size and layout of the engine can vary, but the basic principle remains the same. As fuel is burned, it releases energy, which is converted into mechanical energy that powers the car. This process happens in cylinders with pistons moving inside them, and the crankshaft turns to power the wheels. In my experience, understanding the engine helps in recognizing how incredible this engineering is, turning small explosions into torque that drives a vehicle forward.

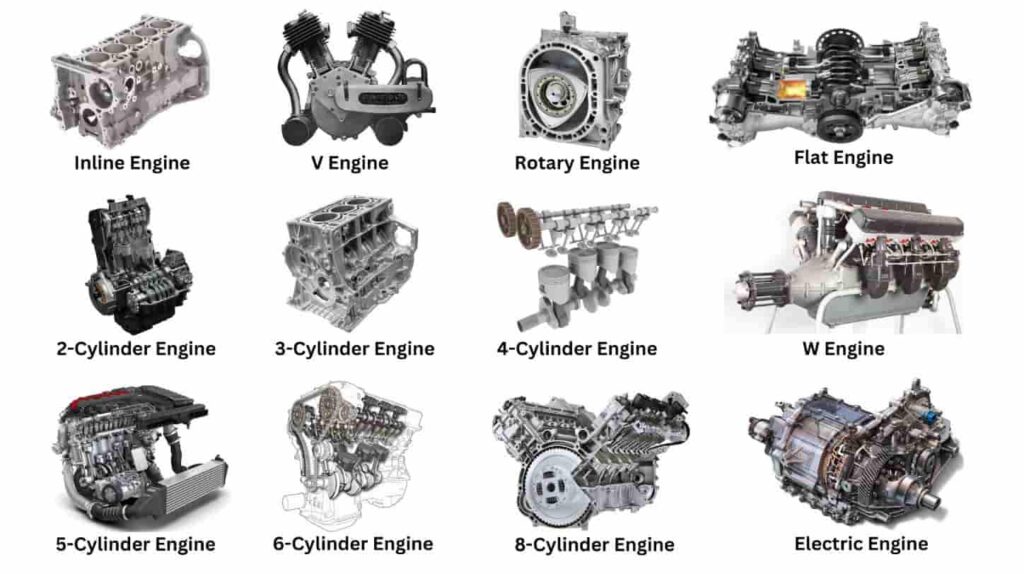

Types Of Engines

When it comes to understanding engines, it’s essential to know that they can be broadly categorized into internal combustion (IC) and external combustion (EC) types. Internal combustion engines are commonly used in most vehicle engines, including cars. In these engines, fuel is mixed with air and burned inside a cylinder, creating heat that pushes pistons to move. This process occurs in four strokes: intake, compression, combustion, and exhaust. The fuel is ignited within the engine, and as it burns, it releases energy that powers the vehicle. With different types of IC engines, such as twin-cylinder or six-cylinder, the layout and design of the engine can vary to achieve different torque and fuel efficiency based on the vehicle’s needs.

On the other hand, external combustion engines work by burning fuel outside the engine to produce heat, which is transferred to a working fluid like water or air. These engines, such as the traditional steam engine, were pivotal during the industrial revolution. In an external combustion engine, heat is used to cause thermal dilation and contraction in the working fluid, which moves and powers the engine. While EC engines are less common in vehicles today, their working principle still offers insight into the ways heat can be used to drive mechanical energy.

In the modern age, hybrid and electric engines have emerged as alternatives to traditional IC engines, offering eco-friendly options that reduce emissions and improve fuel efficiency. Hybrid engines combine the best of both worlds, using an internal combustion engine and an electric motor to power the vehicle. Electric engines rely on electricity stored in batteries to create motion, providing a cleaner, more efficient driving experience. Whether it’s the layout of the engine, such as a V or inline configuration, or the choice of engine type, understanding the differences helps you make an informed decision when choosing a vehicle based on your preferences and driving style.

1. External Combustion Engine

External combustion engines (EC engines) work by burning fuel in a separate chamber, with the heat transferred to a working fluid like steam or air through a heat exchanger. This design, often seen in steam engines—the grandfather of modern machines from the industrial revolution—relies on the thermal dilation and contraction of the fluid, which remains chemically unchanged. Unlike internal combustion (IC) engines, where an air-fuel mixture burns directly inside the engine, EC engines obtain heat indirectly. Systems like the Stirling engine and organic Rankine cycle demonstrate how fluids undergo phase changes or stay gaseous to produce mechanical power. Depending on the setup, these engines may operate in open-cycle or closed-cycle modes, offering unique advantages over their IC counterparts.

2. Internal Combustion Engine

Internal combustion engines (ICE) generate automotive power by burning fuel and air in a confined space called the combustion chamber. This combustion process triggers an exothermic reaction with an oxidizer, producing high-temperature, high-pressure gases that expand rapidly. These expanding hot gases act on pistons or rotors, creating movement that powers the engine. In a four-stroke cycle—intake, compression, power, and exhaust strokes—the mixed air is sucked into the cylinder, compressed, and then ignited. A spark starts the reaction in spark-ignition gasoline engines, while compression-ignition diesel engines rely on a metered spray of fuel that ignites under pressure.

The power strokes from these controlled explosions push the pistons, rotate the crankshaft, and move the vehicle forward. This design allows the engine to operate smoothly and efficiently, adapting to various types of fuels. Whether using gasoline or diesel, these engines have been the mainstay of automotive engineering, offering reliable performance through precise coordination of all components.

3. Hybrid Engine

A hybrid engine combines a petrol engine with an electric motor, creating a versatile and efficient powertrain. This system uses a high-voltage battery to store electrical energy, which powers the electric motor during city driving or at lower speeds, while the combustion engine operates at higher speeds or when additional power is needed. Hybrids excel in fuel efficiency, especially in stop-and-go traffic, thanks to regenerative braking. This innovative process recovers energy from kinetic energy lost during braking and stores it as electrical energy in the battery for later use.

What makes hybrid vehicles so unique is their ability to seamlessly switch between electric-only, petrol-only, or a combination of both modes, depending on speed, load, and driving conditions. The control system manages the power flow, ensuring optimal performance while minimizing fuel consumption and emissions. For example, in electric mode, hybrids produce zero emissions, making them an eco-conscious choice for sustainable transportation. Additionally, features like start-stop systems, which shut off the engine when the car stops, and continuously variable transmissions help further conserve fuel and enhance the driving experience.

By combining the strengths of internal combustion engines and electric motors, hybrids offer a cost-effective solution for reducing vehicle costs over time while promoting a cleaner environment. With automakers continually improving designs to maximize fuel savings, these vehicles provide a sustainable and performance-driven alternative for modern transportation needs.

4. Electric Engine

Electric engines are transforming how vehicles operate by relying on electricity stored in batteries rather than gas or explosive combustion to generate energy for locomotion. Unlike internal combustion engines (ICE), an electric motor uses electromagnetism to convert electrical energy into mechanical power. When an electric current flows through a coil of wire, it interacts with a magnetic field, causing the rotor to spin. This rotational motion propels the car forward by directly driving the wheels, ensuring a quiet, efficient, and zero-emissions ride.

What sets electric vehicles (EVs) apart is their simplicity and high performance. With fewer moving parts compared to traditional combustion engines, they demand lower maintenance while delivering instant torque for swift acceleration. Their lithium-ion batteries not only store and supply energy efficiently but also power motors capable of achieving remarkable efficiency. Whether paired with two motors or even four motors for advanced setups, the design ensures seamless operation, making EVs ideal for a range of applications, from city commutes to high-performance driving.

As technology advances, electric engines are becoming more accessible and practical for everyday use. They represent an eco-friendly alternative to traditional combustion engines, offering a sustainable future in transportation. By combining clean energy with innovative design, electric vehicles are paving the way for a quieter, more efficient, and environmentally-conscious era of mobility.

5. Steam Engines

Steam engines are heat engines that generate mechanical power by using steam pressure as the driving force. These engines work by heating water in a boiler to produce steam, which is then directed into a cylinder or turbine. In reciprocating engines, the steam pressure moves a piston, creating linear motion that is converted into rotational force through a connecting rod and crank. For smoother and continuous rotary motion, steam turbines use a high-pressure rotor to produce energy. These engines played a critical role in powering trains, ships, and early power plants by burning fuel such as coal or natural gas.

A notable feature of steam engines is their reliance on the Rankine cycle, a thermodynamic process that maximizes energy from combustion products. From the early beam engines to Hero’s aeolipile, these engines served various applications, from railway locomotives to stationary steam plants. Their ability to produce reliable mechanical work made them invaluable during the industrial era, and they remain a landmark in the development of external combustion engines.

6. Gas Turbine Engines

Gas turbine engines use the expansion of hot gases to generate power efficiently. They work by compressing air, mixing it with fuel, and burning the mixture to produce hot gases, which expand through a turbine. The rotating turbine drives a shaft that powers a compressor or a load like a generator or propeller. With their excellent power-to-weight ratio, these engines are widely used in aircraft and power plants. Modern systems often include combined thermodynamic cycles to boost efficiency by using exhaust heat recovery to produce steam and capture additional energy. This approach makes them both powerful and versatile for high-output applications.

7. Rocket Engines

Rocket engines work on the principle of action and reaction, where thrust is generated by burning fuel and an oxidizer to produce hot gases. These gases are expelled at high speed through a nozzle, creating a force that pushes the vehicle forward. Used in rockets, missiles, and spacecraft, they operate in both air and space without needing atmospheric oxygen. Solid, liquid, and hybrid rocket fuels offer varied performance and control, with liquid systems being flexible and restartable, while solid fuels are simple and reliable. This makes them vital for launching payloads like satellites and space probes into Earth orbit and beyond.

8. Stirling Engines

Stirling engines are unique because they use an external heat source to heat and cool a working fluid like air or hydrogen in a sealed cylinder. The piston or rotor moves as the fluid expands when heated and contracts when cooled, generating power. These engines are highly efficient and produce low emissions, making them ideal for small-scale applications such as portable generators or refrigeration units. They can even use solar energy or a variety of fuels for heating, making them a versatile and environmentally friendly option. For larger setups, Stirling engines are also used in power plants, where they can provide large-scale power with reduced environmental impact.ips

9. Wankel Engines

Wankel engines, invented by Felix Wankel, use a unique rotary design with a triangular rotor inside an oval-shaped chamber. This design allows the fuel-air mixture to expand and generate power as the rotor spins, delivering continuous motion to drive a car or even a generator. Known for their compact size and high power-to-weight ratio, Wankel engines are lightweight, efficient, and easy to maintain, making them ideal for smaller, portable applications. Their few moving parts also make them simpler than other engines, though they may not be as widely used as other types.

10. Pneumatic Engines

Pneumatic engines use compressed air to generate power. A compressor stores air in a tank, and when the valve is opened, the compressed air is released to push a piston or rotor, which drives a tool or machine. These engines are commonly found in industrial applications, such as pneumatic tools and control systems, where their simplicity and low cost make them an attractive option. They are efficient, easy to maintain, and safe, with no harmful emissions. However, their performance is limited by the amount of air that can be stored in the tank.

Different Types Of Internal Combustion Engines

Internal combustion engines come in various types, each designed for specific work cycles, fuel types, and configurations. They differ based on arrangement of cylinders, number of strokes, and ignition types, and are tailored for specific industries like automotive, aviation, and shipping. Common classifications include four-stroke and two-stroke engines, with variations in cooling methods and valve arrangements. These engines play a critical role in vehicles, generators, and other machines, offering flexibility and power in a range of applications.

V Style Engines

V-style engines are a popular engine design found in many vehicles today. In these engines, the cylinders are arranged in a V-shape with an angle between them, typically 90 degrees. This configuration allows for a compact and efficient engine layout, often with 6 cylinders (V-6), 8 cylinders (V-8), or 12 cylinders (V-12). These engines are commonly used in larger family vehicles, trucks, and high-performance cars like the Ford F-150, Honda Ridgeline, and Ford Expedition. Their design offers a good balance of power, towing capacity, and engine displacement, but they can also be expensive to maintain due to their complex nature and the additional cylinders.

The V engine layout consists of two sets of cylinders positioned at an angle, with a crankshaft connecting them. This design allows for more cylinders in a smaller space, offering greater power while still being relatively compact. As a result, V-style engines are well-suited for vehicles where space is at a premium, like in luxury cars or high-performance vehicles. Brands like Mercedes-Benz, Ferrari, and Alfa Romeo use these engines to provide faster performance, although they can be costly and require more maintenance compared to simpler engine types.

Flat Engines

Flat engines, also known as boxer engines, have a unique design where the cylinders are arranged horizontally, with each piston moving in opposite directions, almost like fighters in a boxing match. This arrangement helps reduce vibrations, making these engines well-balanced and easier to handle. Popular brands like Porsche, Subaru, and BMW use these flat engines for their high-performance vehicles. The design offers a wide form and low profile, allowing for better balance in the vehicle. However, flat engines can be expensive and complex to build, often found in sports cars and premium models, such as Porsche’s 2021 lineups. While these engines offer excellent performance, they can be harder to understand for some, but they remain a great choice for those seeking a powerful, well-balanced driving experience.

Rotary Engines

Rotary engines, also known as Wankel engines, are a unique type of internal combustion engine that uses a triangular rotor instead of the traditional pistons. This design allows for a simple and compact engine with fewer moving parts, making it easier to maintain and repair compared to other engine types. The rotary engine operates with a circular motion, where the rotor moves within a housing, performing the four jobs of intake, compression, combustion, and exhaust. Unlike the up-and-down motion of pistons in piston engines, the rotary motor’s movement is more fluid and continuous, giving the engine its distinctive smooth operation and high RPM capabilities.

Rotary engines are often found in Mazda vehicles, such as the Cosmo, RX-7, and RX-8, where they provide a low-displacement design and unique performance characteristics. While rotary engines have been an alternative to piston-driven engines, they are less common in modern vehicles due to challenges with engine failure and the need for skilled mechanics to maintain them. Despite these challenges, their compact size, fewer components, and distinctive sound make them a favorite among car enthusiasts. Rotary engines can also be found in some aircraft and sports cars, but their use in larger vehicles like V6 or V-style engines remains rare due to their limited power for towing or handling heavier loads.